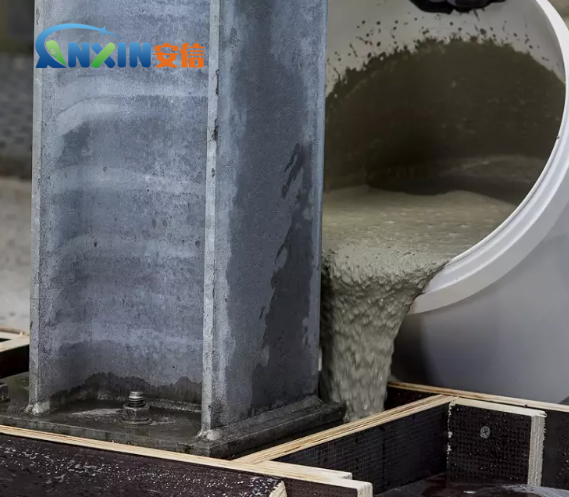

Raws li cov khoom siv hauv tsev siv dav hauv kev tsim kho kev lag luam, mortar plays lub luag haujlwm tseem ceeb hauv kev tsim thiab ua haujlwm. Lub fluidity ntawm mortar yog ib qho ntawm cov cim tseem ceeb uas cuam tshuam rau nws txoj kev tsim kho. Zoo fluidity pab txhawb kom yooj yim ntawm kev tsim kho kev lag luam thiab lub tsev zoo. Txhawm rau txhim kho qhov fluidity thiab kev ua haujlwm ntawm mortar, ntau yam khoom siv feem ntau siv rau kev hloov kho. Ntawm lawv,Hydroxypropyl methylcellulose (HPMC), raws li feem ntau siv dej-soluble polymer compound, plays lub luag haujlwm tseem ceeb hauv mortar. .

Cov yam ntxwv tseem ceeb ntawm HPMC: HPMC yog cov khoom siv dej-soluble polymer ua los ntawm cov tshuaj hloov kho ntuj tsim cellulose. Nws muaj cov thickening zoo heev, gelling, dej tuav thiab lwm yam khoom. Nws yog insoluble hauv dej, tab sis tuaj yeem tsim cov kua dej khov hauv dej, yog li nws feem ntau siv dav hauv kev tsim kho, txheej, tshuaj thiab lwm yam. Thaum siv los ua cov tshuaj khib nyiab, HPMC tuaj yeem txhim kho cov dej ntws zoo, tuav dej thiab ua haujlwm ntawm cov mortar.

Kev cuam tshuam ntawm HPMC ntawm mortar fluidity:

Thickening nyhuv: HPMC nws tus kheej muaj cov nyhuv thickening tseem ceeb. Thaum ntxiv rau mortar, nws tuaj yeem ua kom cov viscosity ntawm cov tshuaj khib. Cov nyhuv thickening yog vim HPMC molecules tsim ib lub network qauv hauv dej, uas absorbs dej thiab nthuav, ua rau cov viscosity ntawm cov dej theem. Cov txheej txheem no tso cai rau lub fluidity ntawm mortar hloov. Thaum HPMC cov ntsiab lus nyob rau hauv mortar siab, cov dej dawb ntws yuav raug txwv rau qee yam, yog li tag nrho cov fluidity ntawm mortar yuav qhia tau qee yam kev hloov pauv.

Txhim kho cov dej tuav: HPMC tuaj yeem tsim cov zaj duab xis nyias hauv cov mortar kom txo cov dej evaporation thiab txhim kho cov dej tuav ntawm cov mortar. Cov khib nyiab nrog cov dej tuav tau zoo tuaj yeem tswj xyuas kev ua haujlwm tau ntev dua, uas yog qhov tseem ceeb rau kev yooj yim ntawm kev tsim kho thaum tsim kho. Kev tuav dej siab tuaj yeem tiv thaiv cov mortar los ntawm kev ziab ntxov ntxov thiab txhim kho lub sijhawm tsim kho thiab kev ua haujlwm ntawm cov mortar.

Dispersion: HPMC tuaj yeem tsim cov tshuaj colloidal hauv dej, uas tuaj yeem txhim kho qhov tawg ntawm cov khoom siv tshuaj khib nyiab. Lub fluidity ntawm mortar tsis yog tsuas yog cuam tshuam nrog kev faib ua feem ntawm cov cement, xuab zeb thiab admixtures, tab sis kuj tseem cuam tshuam nrog kev tawg ntawm cov khoom no. Los ntawm kev kho tus nqi ntawm HPMC, cov khoom nyob rau hauv lub mortar yuav dispersed ntau tusyees, yog li ntxiv txhim kho lub fluidity.

Gelling nyhuv: HPMC tuaj yeem txhawb nqa kev faib tawm ntau dua ntawm cov khoom hauv mortar thiab txhim kho kev ruaj ntseg ntawm nws cov qauv. Los ntawm kev txhim kho cov nyhuv gelling, HPMC tuaj yeem tswj cov kua dej ruaj khov ntawm cov tshuaj khib nyiab thaum lub sijhawm khaws cia ntev thiab zam kom tsis txhob muaj dej txaus vim lub sijhawm qeeb.

Plasticity li nyhuv: Qhov sib ntxiv ntawm HPMC kuj tuaj yeem txhim kho cov yas ntawm cov mortar, ua kom yooj yim rau kev khiav lag luam thiab muaj cov yas zoo dua thaum lub sij hawm tsim kho. Piv txwv li, thaum plastering phab ntsa, kom zoo fluidity thiab plasticity tuaj yeem txo qhov tshwm sim ntawm cov kab nrib pleb thiab txhim kho qhov zoo ntawm plastering.

Optimized daim ntawv thov ntawm HPMC nyob rau hauv mortar fluidity hloov:

Kev tswj kev noj tshuaj: Qhov ntau npaum ntawm HPMC cuam tshuam ncaj qha rau cov kua dej ntawm cov tshuaj khib nyiab. Feem ntau hais lus, thaum qhov sib ntxiv ntawm HPMC yog nruab nrab, qhov dej thiab dej tuav ntawm cov tshuaj khib nyiab tuaj yeem txhim kho tau zoo. Txawm li cas los xij, HPMC ntau dhau tuaj yeem ua rau cov viscosity ntawm cov tshuaj khib nyiab siab dhau, uas ua rau txo nws cov dej ntws. Yog li, tus nqi ntawm HPMC ntxiv yuav tsum tau tswj kom raug raws li cov kev xav tau tshwj xeeb hauv cov ntawv thov.

Synergy nrog rau lwm yam admixtures: Ntxiv rau HPMC, lwm yam admixtures feem ntau ntxiv rau mortar, xws li superplasticizers, retarders, thiab lwm yam. poj niam deev. Piv txwv li, superplasticizers tuaj yeem txo cov dej hauv mortar thiab txhim kho cov kua dej ntawm cov tshuaj khib nyiab, thaum HPMC tuaj yeem txhim kho nws cov dej tuav thiab kev tsim kho kev ua haujlwm thaum tswj cov viscosity ntawm mortar.

Kev hloov ntawm ntau hom mortar: Ntau hom mortar muaj qhov sib txawv fluidity. Piv txwv li, plastering mortar muaj cov kev xav tau ntau dua, thaum masonry mortar them ntau xim rau nws cov kev sib txuas thiab thickness. Thaum lub sij hawm tus txheej txheem no, tus nqi thiab hom HPMC ntxiv yuav tsum tau optimized thiab kho raws li qhov yuav tsum tau ntawm cov mortars sib txawv los xyuas kom meej zoo fluidity thiab sib npaug.

Raws li feem ntau siv mortar additive,HPMCNws tuaj yeem kho qhov fluidity ntawm mortar los ntawm thickening, dej tuav, dispersion, gelling, thiab lwm yam. Txawm li cas los xij, qhov ntau npaum li cas ntawm HPMC yuav tsum tau kho kom raug raws li kev thov tshwj xeeb kom tsis txhob siv ntau dhau uas ua rau txo cov dej ntws. Nrog rau kev txhim kho tas mus li ntawm kev ua tau zoo ntawm mortar hauv kev tsim kho kev lag luam, kev tswj hwm ntawm HPMC muaj kev thov dav dav rau yav tom ntej.

Post lub sij hawm: Jan-10-2025