HydroxyPropylropy Cellulose (HPMC)Yog ib qho tseem ceeb tshaj plaws ether, uas tau siv dav hauv cov ntaub ntawv hauv tsev, tshwj xeeb tshaj yog cov tshuaj khib ua dej rov qab thiab cov tuab tuab. Cov dej khaws cov nyhuv ceev ntawm HPMC hauv kev ua haujlwm ncaj qha cuam tshuam rau kev tsim kho thiab lub zog txhim kho ntawm lub luag haujlwm tseem ceeb hauv kev tsim kho cov phiaj xwm.

1. Cov dej rov qab los yuav tsum tau ua thiab cuam tshuam rau hauv cult.

Tshuaj khib yog cov khoom siv nplaum uas siv tau siv rau cov txheej txheem kev tsim kho, kho kom huv, kho cov khoom siv ntawm cov dej noo kom ntseeg tau tias ua haujlwm zoo thiab cov nplaum. Sai sai evaporation ntawm dej nyob rau hauv lub tshuaj txug lossis dej loj heev yuav ua rau cov teeb meem hauv qab no:

Txo lub zog: Dej poob yuav ua rau tsis txaus ntseeg txoj kev ywj siab; yog li cuam tshuam lub zog txhim kho ntawm lub tshuaj khib.

Kev sib raug zoo tsis txaus: Dej poob yuav ua rau muaj kev sib cais tsis txaus ntawm lub tshuaj khib thiab txheej, cuam tshuam rau kev ruaj ntseg ntawm lub tsev qauv.

Cov tawg tawg thiab khoob: Cov ntaub ntawv tsis sib xws ntawm cov dej tuaj yeem ua rau cov txheej txheem currinkage thiab tawg ntawm cov tsos thiab kev pabcuam lub neej.

Yog li ntawd, lub tshuaj khib yuav tsum muaj lub peev xwm dej ua kom muaj zog thaum kev tsim kho cov dej tawm, thiab HPMC tuaj yeem txhim kho kev tsim kho cov khoom lag luam thiab qhov zoo ntawm cov khoom tiav.

2. Dej ceev ceev tshuab ntawm HPMC

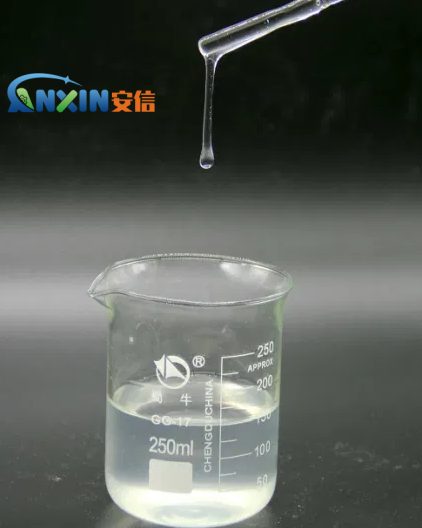

HPMC muaj cov dej muaj zog heev, feem ntau vim yog nws cov qauv molecular thiab tshwj xeeb mechanism hauv cov tshuaj tua hluav taws:

Kev nqus dej nqus thiab nthuav dav: muaj ntau pawg hydroxyl hauv HPMC, uas tuaj yeem tsim cov lwg hydrogen nrog cov roj av, ua rau nws cov dej ntws heev. Tom qab ntxiv dej, HPMC lwg me me tuaj yeem nqus tau ntau cov dej thiab nthuav los ua cov khoom siv gel gel loj, yog li ncua cov dej evaporation thiab poob dej.

Zaj duab xis tsim cov yam ntxwv: HPMC yaj nyob rau hauv dej los ua kev daws teeb meem siab, uas tuaj yeem tsim zaj duab xis ib ncig ntawm cov tshuaj khib. Qhov kev tiv thaiv kev tiv thaiv no tsis tuaj yeem xauv cov nyhav rau hauv noo noo rau lub substrate rau lub substrate rau lub substrate rau lub substure, li kev txhim kho cov dej tuav ntawm lub tshuaj khib.

Thickening cov nyhuv: tom qab HPMC yog yaj hauv dej, nws yuav ua rau cov kab tsuag, uas pab kom cov dej khov kho thiab khaws dej thiab tiv thaiv kom nrawm dua. Cov nyhuv tuab kuj tseem tuaj yeem txhim kho cov haujlwm ntawm cov tshuaj khib thiab txhim kho nws cov kev ua haujlwm ntawm kev tawm suab.

3. HPMC dej ceev ceev txhim kho cov kev ua tshuaj cug

HPMC txhim kho cov dej tshem tawm ntawm cug, uas tsis ncaj qha muaj kev cuam tshuam zoo rau nws lub cev nqaij daim tawv thiab tshuaj lom neeg. Nws yog tshwj xeeb qhia hauv qab no:

3.1 Txhim kho qhov ua haujlwm ntawm cug

Cov haujlwm zoo ua tau tuaj yeem ua kom muaj kev tsim kho kom zoo nkauj. HPMC nce viscosity thiab dej ceev ceev ntawm cug, yog li ntawd lub tshuaj khib nyob hauv cov txheej txheem tsim kho, thiab precipitate dej, yog li kev txhim kho zoo heev ntawm kev tsim kho.

3.2 polong lub sijhawm qhib

Kev txhim kho HPMC cov dej khaws cia tuaj yeem ua kom lub tshuaj khib nyiab kom ntev dua, ntev dua, thiab ua kom lub sijhawm qhib hluav taws xob, thiab txo qhov kev sib xyaw ntawm cov dej nrawm thaum tsim kho. Qhov no muab cov neeg siv kev cog lus uas muaj lub sijhawm hloov kho dua thiab pab txhim kho kom zoo siv.

3.3 Txhim kho qhov sib khi ua lub zog ntawm cug

Daim ntawv cog lus lub zog ntawm coll cug yog cuam tshuam ze rau cov kev nyiam cov tshuaj tiv thaiv ntawm cov cement. Cov dej khaws cia los ntawm HPMC ua kom cov Maas ua kom tau txais kev sib raug zoo, tsis txhob txhim kho cov kab cug thaum ntxov thiab lub substrate.

3.4 Txo cov shrinkage thiab tawg

HPMC muaj dej zoo heev ua tau zoo, uas tuaj yeem txo cov dej tsis huv, yog li kev teeb tsa cov tsos ntawm lub ntsej muag, thiab txhim kho cov tsos thiab ruaj khov.

3.5 txhim kho lub khov-thaws ua hauj lwm cug

Dej khaws cia ntawmHPMCUa rau cov dej hauv lub tshuaj tsuag eYly faib, uas pab kom txhim kho qhov ntom ntom thiab kev sib xyaw ntawm lub cug. Cov qauv kev coj ua no tuaj yeem tiv thaiv kev puas tsuaj los ntawm khov-lub voj voog ua rau huab cua txias thiab txhim kho lub zog hluav taws xob.

4. Kev sib raug zoo ntawm tus nqi HPMC thiab cov dej khaws cia

Tus nqi HPMC ntxiv yog qhov tseem ceeb heev rau cov dej ua kom ruaj khov ntawm lub tshuaj khib. Feem ntau hais lus, ntxiv qhov tsim nyog HPMC tuaj yeem txhim kho cov dej khib nyiab, nws yuav ua rau lub tshuaj khib nyiab, nws yuav ua rau lub tshuaj khib nyiab ntau, nws yuav ua rau lub captiver, cuam tshuam rau kev tsim kho cov haujlwm thiab lub zog tom qab ua kom tawv. Yog li ntawd, hauv cov ntawv thov siv, tus nqi HPMC yuav tsum tau tswj hwm raws li cov tshuaj thiab cov kev tsim kho ntawm cov tshuaj khib kom ua tiav cov txiaj ntsig kom ua tau zoo.

Raws li cov dej tseem ceeb-khaws cia tus neeg sawv cev thiab cov tuab dua, HPMC plays ib lub luag haujlwm ntawm Irreplacleable lub luag haujlwm hauv kev txhim kho cov dej rov qab los ntawm cug. It can not only significantly improve the workability and construction performance of mortar, but also effectively prolong the open time, enhance the bonding strength, reduce shrinkage cracking, and improve the durability and freeze-thaw resistance of mortar. Hauv kev tsim kho Niaj hnub no, cov ntawv teev tsim nyog HPMC tsis tuaj yeem daws tau qhov teeb meem ntawm txoj haujlwm cug dej ploj, tab sis kuj tseem ua tau zoo ntawm lub neej ntawm lub tsev.

Lub Sijhawm Post: Nov-12-2024