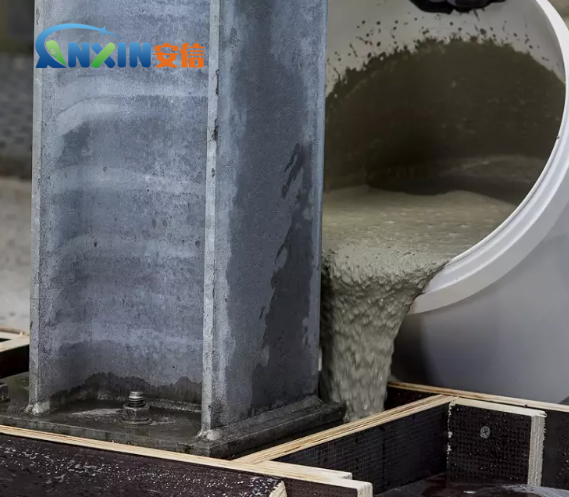

Njengempahla yokwakha esetshenziswa kabanzi embonini yezokwakha, udaka ludlala izindima ezibalulekile zesakhiwo nokusebenza. I-fluidity of mortar ingenye yezinkomba ezibalulekile ezithinta ukusebenza kwayo kokwakhiwa. I-fluidity enhle inomthelela ekwenzeni imisebenzi yokwakha kanye nekhwalithi yesakhiwo. Ukuze kuthuthukiswe uketshezi nokusebenza kodaka, izithasiselo ezihlukahlukene zivame ukusetshenziselwa ukulungiswa. Phakathi kwazo,i-hydroxypropyl methylcellulose (HPMC), njengengxube ye-polymer encibilikayo evame ukusetshenziswa emanzini, idlala indima ebalulekile odakeni. .

Izici eziyisisekelo ze-HPMC: I-HPMC iwumsebenzi we-polymer encibilika emanzini owenziwe nge-cellulose yemvelo eguqulwe ngamakhemikhali. Inokuqina okuhle kakhulu, i-gelling, ukugcinwa kwamanzi nezinye izakhiwo. Ayincibiliki emanzini, kodwa ingakha isixazululo se-viscous emanzini, ngakho-ke ivame ukusetshenziswa kakhulu ekwakhiweni, ekugqokeni, emuthini nakwezinye izinkambu. Uma isetshenziswa njengesengezo sodaka, i-HPMC ingathuthukisa ngempumelelo uketshezi, ukugcinwa kwamanzi kanye nokusebenza kodaka.

Indlela yethonya ye-HPMC ku-mortar fluidity:

Ukuqina komphumela: I-HPMC ngokwayo inomphumela wokujiya obalulekile. Uma yengezwe odakeni, ingakhuphula kakhulu i-viscosity yodaka. Umphumela wokuqina ubangelwa ama-molecule e-HPMC enza isakhiwo senethiwekhi emanzini, esithatha amanzi futhi sinwebe, okwandisa i-viscosity yesigaba samanzi. Le nqubo ivumela uketshezi lodaka ukuthi lulungiswe. Uma okuqukethwe kwe-HPMC kudaka kuphezulu, ukugeleza kwamanzi mahhala kuzokhawulelwa ngezinga elithile, ngakho-ke uketshezi lulonke lodaka luzobonisa izinguquko ezithile.

Thuthukisa ukugcinwa kwamanzi: I-HPMC ingakha ifilimu elincanyana odakeni ukuze kuncishiswe ukuhwamuka kwamanzi futhi kuthuthukise ukugcinwa kwamanzi odaka. Udaka olugcina amanzi kangcono lungakwazi ukugcina ukusebenza isikhathi eside, okubalulekile ukuze kube lula ukwakha ngesikhathi sokwakha. Ukugcinwa kwamanzi okuphezulu kungavimbela udaka ukuthi lome ngaphambi kwesikhathi futhi kuthuthukise isikhathi sokwakha nokusebenza kahle kodaka.

Ukuhlakazwa: I-HPMC ingakha isixazululo se-colloidal emanzini, esingathuthukisa ukuhlakazeka phakathi kwezingxenye zodaka. I-fluidity ye-mortar ayihlobene kuphela nengxenye yesimende, isihlabathi kanye ne-admixtures, kodwa futhi ihlobene eduze nokuhlakazeka kwalezi zingxenye. Ngokulungisa inani le-HPMC, izingxenye ezisesimendeni zingahlakazwa ngokulinganayo, ngaleyo ndlela kuthuthukiswe uketshezi.

Umphumela we-Gelling: I-HPMC ingakhuthaza ukusatshalaliswa okulinganayo kwezinhlayiya odakeni futhi ithuthukise ukuqina kwesakhiwo sayo. Ngokwenza ngcono umthelela we-gelling, i-HPMC ingakwazi ukugcina ukugeleza kodaka okuzinzile phakathi nokugcinwa kwesikhathi eside futhi igweme ukwehla koketshezi ngenxa yokubambezeleka kwesikhathi.

Umphumela wokuthuthukisa i-Plastiki: Ukwengezwa kwe-HPMC kungabuye kuthuthukise ipulasitiki yodaka, kwenze kube lula ukusebenza nokuba nepulasitiki engcono ngesikhathi senqubo yokwakha. Isibonelo, lapho ukhonkotha udonga, uketshezi olufanele kanye nepulasitiki kunganciphisa ukuvela kwemifantu futhi kuthuthukise ikhwalithi yokukhonkoloza.

Ukusetshenziswa okulungiselelwe kwe-HPMC ekulungiseni uketshezi olunodaka:

Ukulawulwa komthamo: Umthamo we-HPMC uthinta ngqo uketshezi lodaka. Ngokuvamile, uma inani elingeziwe le-HPMC limaphakathi, uketshezi kanye nokugcinwa kwamanzi kodaka kungathuthukiswa kakhulu. Kodwa-ke, i-HPMC eyeqile ingase ibangele ukuthi i-viscosity yodaka ibe phezulu kakhulu, okubuye kunciphise ukugeleza kwayo. Ngakho-ke, inani le-HPMC elengeziwe lidinga ukulawulwa ngokunembile ngokuya ngezidingo ezithile ezinhlelweni zokusebenza.

I-synergy nezinye izixube: Ngaphezu kwe-HPMC, ezinye izixube zivame ukungezwa odakeni, njengama-superplasticizers, retarders, njll. Ukusebenzisana phakathi kwalezi zingxube ne-HPMC kungalawula kangcono ukugeleza kodaka. ucansi. Isibonelo, ama-superplasticizers anganciphisa inani lamanzi odakeni futhi athuthukise ukugeleza kodaka, kuyilapho i-HPMC ingathuthukisa ukugcinwa kwayo kwamanzi nokusebenza kokwakhiwa ngenkathi igcina i-viscosity yodaka.

Ukulungiswa kwezinhlobo ezihlukene zodaka: Izinhlobo ezahlukene zodaka zinezidingo ezihlukene zoketshezi. Isibonelo, udaka olunamekiwe lunezidingo eziphakeme zokumanzisa, kuyilapho udaka lwamatshe lunaka kakhulu ukubopha nokujiya kwalo. Phakathi nale nqubo, inani kanye nohlobo lwe-HPMC engeziwe kudingeka luthuthukiswe futhi lulungiswe ngokuvumelana nezidingo zodaka oluhlukahlukene ukuze kuqinisekiswe uketshezi oluningi nokulinganisela.

Njengesengezo sodaka esisetshenziswa kakhulu,I-HPMCingalungisa ngokuphumelelayo uketshezi lodaka ngokuqina, ukugcinwa kwamanzi, ukuhlakazeka, i-gelling, njll. Izakhiwo zayo eziyingqayizivele zenza udaka lusebenze kakhulu futhi luzinze ngesikhathi sokwakhiwa. Kodwa-ke, umthamo we-HPMC udinga ukulungiswa ngokunembile ngokuya ngezimo ezithile zohlelo ukuze kugwenywe ukusetshenziswa ngokweqile okuholela ekuncipheni koketshezi. Ngokuthuthukiswa okuqhubekayo kwezidingo zokusebenza kodaka embonini yezokwakha, umphumela wokulawula we-HPMC unamathemba okusebenza abanzi esikhathini esizayo.

Isikhathi sokuthumela: Jan-10-2025