Application of Carboxymethyl Cellulose in Food Industry

Carboxymethyl cellulose (CMC) is a widely used food additive known for its versatile properties. With its ability to act as a thickener, stabilizer, and emulsifier, CMC finds extensive applications in various food products.

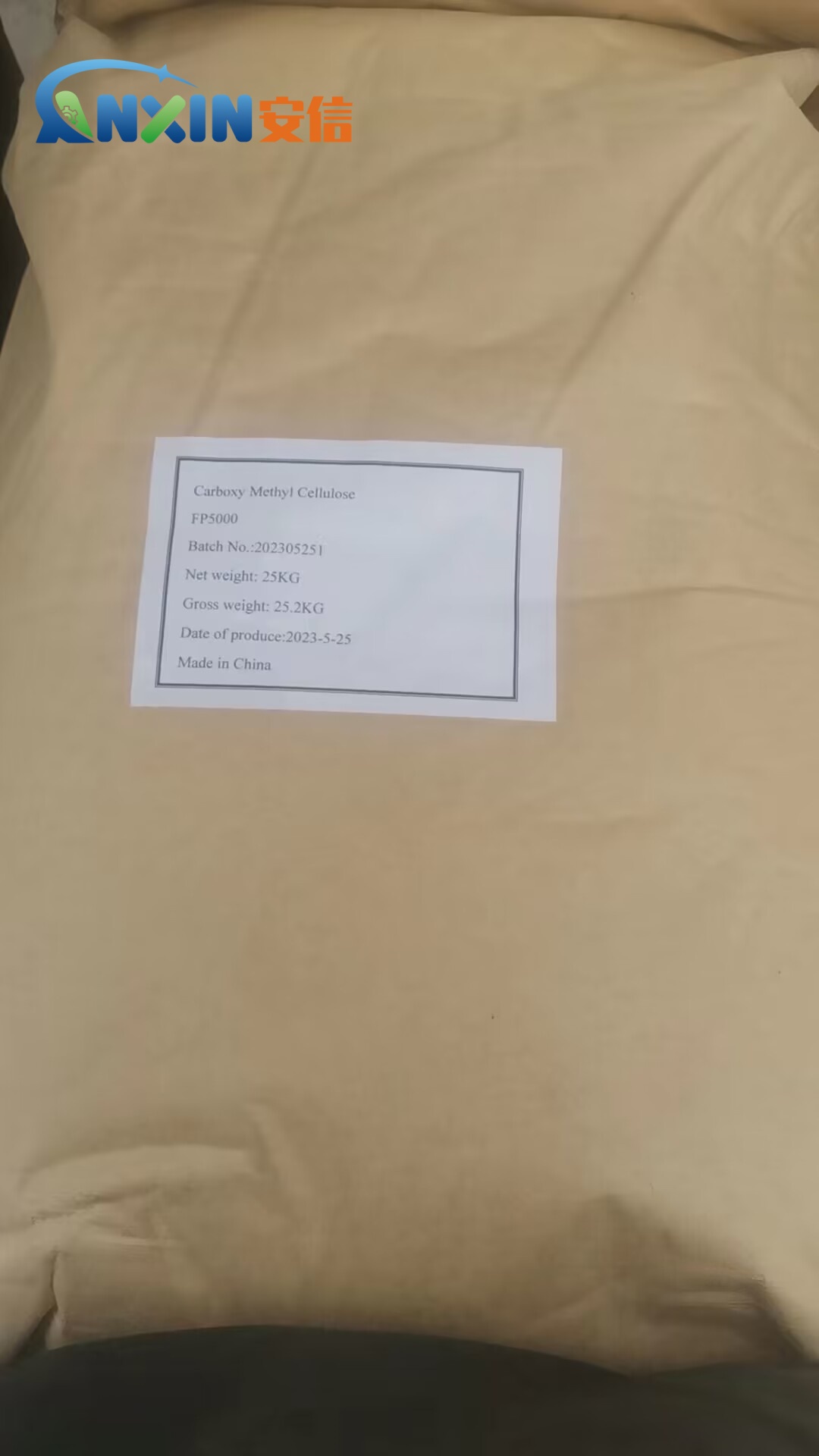

Carboxymethyl cellulose (CMC) is a cellulose derivative derived from natural cellulose sources, such as wood pulp or cotton fibers. It is a water-soluble polymer that has gained significant attention in the food industry due to its unique properties.

Properties of Carboxymethyl Cellulose

Water solubility: CMC exhibits excellent water solubility, making it suitable for use in aqueous food systems.

Rheology modifier: It can modify the rheological properties of food products, providing viscosity and texture control.

Stabilizer: CMC helps stabilize emulsions and suspensions in food formulations.

Film-forming agent: It has the ability to form films, enhancing the shelf life of certain food products.

Non-toxic and inert: CMC is safe for consumption and does not alter the taste or odor of food.

1.Applications of Carboxymethyl Cellulose in Food

a. Bakery Products: CMC improves dough handling properties, enhances volume, and extends the freshness of baked goods.

b. Dairy Products: It stabilizes dairy emulsions, prevents syneresis in yogurts, and improves the texture of ice creams.

c. Sauces and Dressings: CMC acts as a thickener and stabilizer in sauces, gravies, and salad dressings, providing desired viscosity and mouthfeel.

d. Beverages: It stabilizes suspensions in beverages, prevents sedimentation, and improves the overall texture.

e. Confectionery: CMC is used in candies and gummies to adjust texture and prevent sticking.

f. Meat Products: It improves water retention, texture, and binding properties in processed meat products.

g. Gluten-free Products: CMC is utilized as a gluten substitute in gluten-free formulations, providing structure and texture.

2.Benefits of Carboxymethyl Cellulose in Food Applications

Improved Texture: CMC enhances the texture and mouthfeel of food products, contributing to consumer acceptance.

Shelf Life Extension: Its film-forming properties help extend the shelf life of perishable food items by providing a barrier against moisture loss and oxidation.

Stability: CMC stabilizes emulsions, suspensions, and foams, ensuring uniformity and preventing phase separation.

Cost-effectiveness: It offers a cost-effective solution for achieving desired food product attributes compared to other additives.

Versatility: CMC is compatible with a wide range of food ingredients and processes, making it suitable for various applications.

3.Regulatory Status and Safety Considerations

CMC is approved for use as a food additive by regulatory agencies such as the FDA (Food and Drug Administration) in the United States and the EFSA (European Food Safety Authority) in Europe.

It is generally recognized as safe (GRAS) when used within specified limits in food products.

Adherence to Good Manufacturing Practices (GMP) is essential to ensure the safe and effective use of CMC in food manufacturing.

4.Future Perspectives

With the increasing demand for clean label and natural ingredients, there is a growing interest in exploring alternative sources of cellulose derivatives that can replace synthetic additives like CMC.

Research efforts are focused on developing innovative formulations and processes to enhance the functionality and sustainability of CMC in food applications.

Carboxymethyl cellulose plays a crucial role in the food industry as a multifunctional additive with diverse applications. Its unique properties contribute to the quality, stability, and consumer appeal of various food products. As regulatory agencies continue to evaluate its safety and efficacy, CMC remains a valuable ingredient for food manufacturers seeking to optimize product performance and meet consumer demands.

Post time: Apr-07-2024