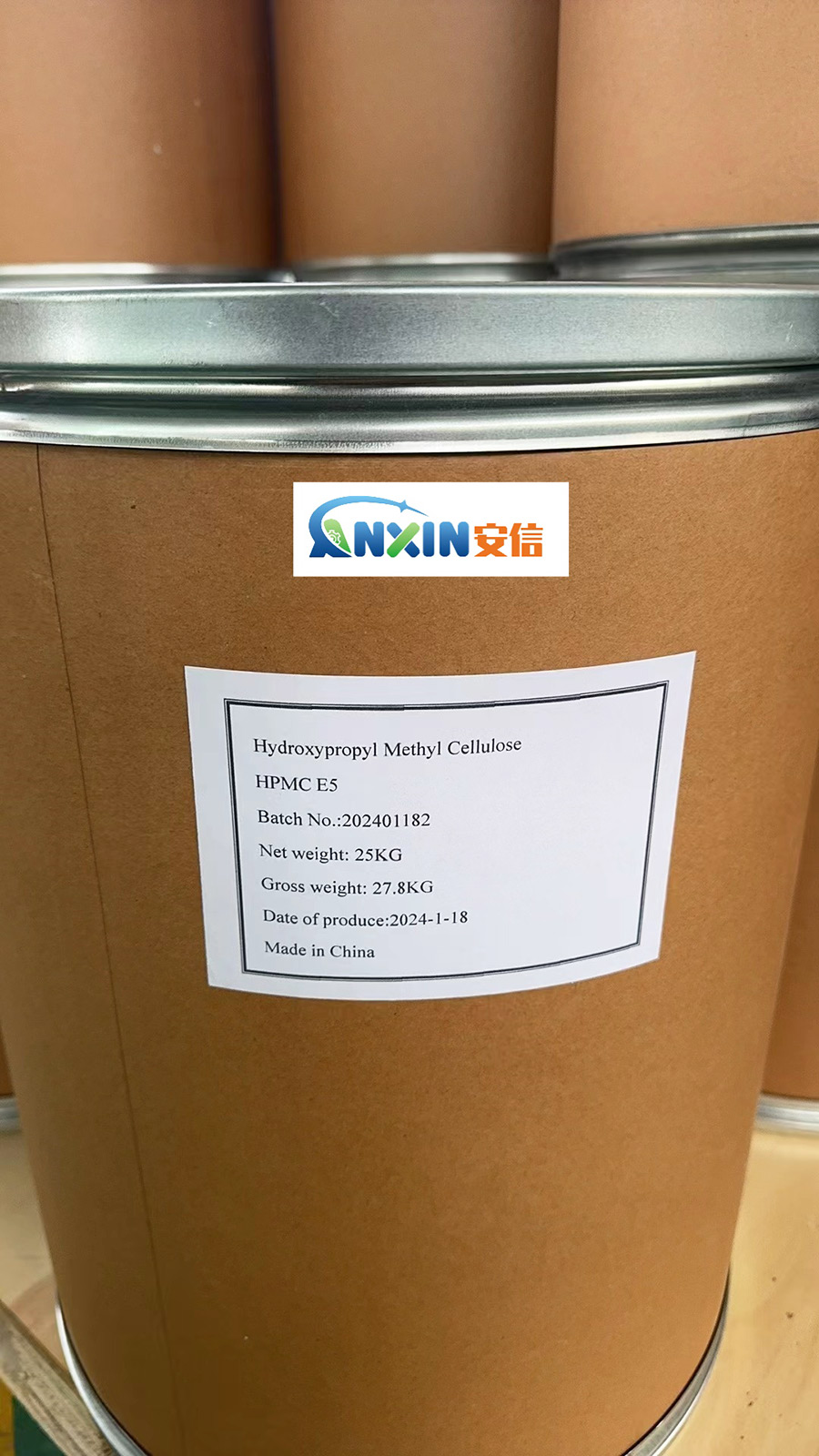

Hydroxypropyl Methylcellulose (HPMC) is a nonionic cellulose ether with good film-forming, adhesion, thickening and controlled release properties, and is widely used in the pharmaceutical industry. As a pharmaceutical excipient, AnxinCel®HPMC can be used in tablets, capsules, sustained-release preparations, ophthalmic preparations and topical drug delivery systems.

1. Physicochemical properties of HPMC

HPMC is a semi-synthetic polymer material obtained by methylating and hydroxypropylating natural cellulose, with excellent water solubility and biocompatibility. Its solubility is less affected by temperature and pH value, and it can swell in water to form a viscous solution, which helps the controlled release of drugs. According to the viscosity, HPMC can be divided into three categories: low viscosity (5-100 mPa·s), medium viscosity (100-4000 mPa·s) and high viscosity (4000-100000 mPa·s), which are suitable for different preparation requirements.

2. Application of HPMC in pharmaceutical preparations

2.1 Application in tablets

HPMC can be used as a binder, disintegrant, coating material and controlled-release skeleton material in tablets.

Binder: HPMC can be used as a binder in wet granulation or dry granulation to improve particle strength, tablet hardness and mechanical stability of drugs.

Disintegrant: Low-viscosity HPMC can be used as a disintegrant to promote tablet disintegration and increase drug dissolution rate after swelling due to water absorption.

Coating material: HPMC is one of the main materials for tablet coating, which can improve the appearance of drugs, cover up the bad taste of drugs, and can be used in enteric coating or film coating with plasticizers.

Controlled-release material: High-viscosity HPMC can be used as a skeleton material to delay drug release and achieve sustained or controlled release. For example, HPMC K4M, HPMC K15M and HPMC K100M are often used to prepare controlled-release tablets.

2.2 Application in capsule preparations

HPMC can be used to produce plant-derived hollow capsules to replace gelatin capsules, which are suitable for vegetarians and people who are allergic to animal-derived capsules. In addition, HPMC can be used for filling liquid or semisolid capsules to improve the stability and release characteristics of drugs.

2.3 Application in ophthalmic preparations

HPMC, as the main component of artificial tears, can increase the viscosity of eye drops, prolong the residence time of drugs on the ocular surface, and improve bioavailability. In addition, HPMC can also be used to prepare eye gels, eye films, etc., to improve the sustained release effect of eye drugs.

2.4 Application in topical drug delivery preparations

AnxinCel®HPMC has good film-forming properties and biocompatibility, and can be used to prepare transdermal patches, gels and creams. For example, in transdermal drug delivery systems, HPMC can be used as a matrix material to increase the drug penetration rate and prolong the duration of action.

2.5 Application in oral liquid and suspension

HPMC can be used as a thickener and stabilizer to improve the rheological properties of oral liquid and suspension, prevent solid particles from settling, and improve the uniformity and stability of drugs.

2.6 Application in inhalation preparations

HPMC can be used as a carrier for dry powder inhalers (DPIs) to improve the fluidity and dispersibility of drugs, increase the lung deposition rate of drugs, and thus enhance the therapeutic effect.

3. Advantages of HPMC in sustained-release preparations

HPMC has the following characteristics as a sustained-release excipient:

Good water solubility: It can quickly swell in water to form a gel barrier and regulate the drug release rate.

Good biocompatibility: non-toxic and non-irritating, not absorbed by the human body, and has a clear metabolic pathway.

Strong adaptability: Suitable for different types of drugs, including water-soluble and hydrophobic drugs.

Simple process: Suitable for a variety of preparation processes such as direct tableting and wet granulation.

As an important pharmaceutical excipient, HPMC is widely used in many fields such as tablets, capsules, ophthalmic preparations, topical preparations, etc., especially in sustained-release preparations. In the future, with the continuous development of pharmaceutical preparation technology, the application scope of AnxinCel®HPMC will be further expanded, providing the pharmaceutical industry with more efficient and safe excipient options.

Post time: Feb-08-2025