The application of redispersible latex powder (RDP) in putty powder formulations has garnered attention in the construction and building materials industry due to its significant impact on the properties of the final product. Redispersible latex powders are essentially polymer powders that are capable of forming dispersions when mixed with water. These dispersions impart various beneficial characteristics to the putty, including improved adhesion, flexibility, water resistance, and, crucially, the hardening process.

Understanding Putty Powder and Redispersible Latex Powder

Putty powder is a fine powder-based product used primarily for filling gaps, smoothing surfaces, and preparing substrates for painting or other finishes. The basic composition of putty powder typically includes binders (e.g., cement, gypsum), fillers (e.g., talc, calcium carbonate), and additives (e.g., retarders, accelerators) that control its working properties. When mixed with water, the putty powder forms a paste that hardens over time, creating a durable, smooth surface.

Redispersible latex powder (RDP) is a water-soluble polymer powder made by spray-drying aqueous dispersions of polymer emulsions. Common polymers used in RDP include styrene-butadiene (SBR), acrylics, and vinyl acetate-ethylene (VAE). The addition of RDP to putty powder enhances the physical and mechanical properties of the cured putty, primarily by improving the bond strength, flexibility, and resistance to cracking.

Hardening of Putty Powder

The hardening of putty powder occurs as the binder components (like cement or gypsum) undergo a chemical reaction with water. The process is generally termed hydration (for cement-based putties) or crystallization (for gypsum-based putties), and it results in the formation of solid phases that harden over time. However, this process can be influenced by a range of factors, such as the presence of additives, humidity, temperature, and the composition of the putty itself.

The role of RDP in this hardening process is to enhance the bonding between the particles, improve flexibility, and regulate the evaporation of water. RDP functions as a binder that, once redispersed in water, forms a polymeric network within the putty. This network helps trap the water molecules longer, slowing down the rate of evaporation and thus extending the working time of the putty. Additionally, the polymer network helps form a stronger, more cohesive hardened mass by improving particle interaction.

Impact of Redispersible Latex Powder on the Hardening Process

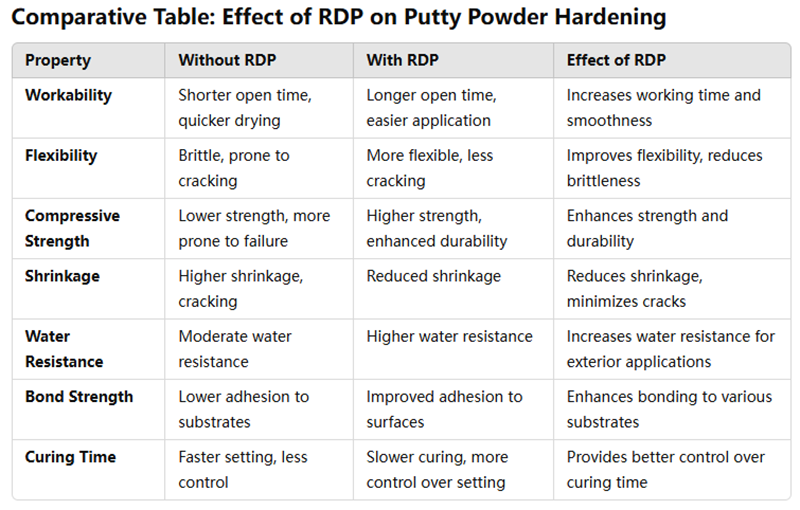

Improved Workability and Open Time:

The inclusion of RDP in putty formulations enhances the workability by slowing down the drying process, giving more time for application. This is particularly beneficial in large projects where the putty needs to be spread over extensive areas before it sets.

Increased Flexibility:

One of the significant effects of adding RDP is an improvement in flexibility. While traditional putty tends to be brittle upon hardening, RDP contributes to a more flexible cured material, reducing the likelihood of cracking under stress or temperature fluctuations.

Strength and Durability:

RDP-modified putties exhibit higher compressive strength and resistance to wear and tear compared to non-modified formulations. This is due to the formation of a polymer matrix that reinforces the structural integrity of the hardened putty.

Reduced Shrinkage:

The polymeric network created by the redispersible latex powder also helps in reducing shrinkage during the curing process. This is particularly important in preventing the formation of cracks, which can compromise the performance and aesthetic of the putty.

Water Resistance:

Putty powder mixed with redispersible latex powder tends to be more water-resistant. The latex particles form a hydrophobic layer within the putty, making the cured product less susceptible to water absorption and, therefore, better suited for exterior applications.

Incorporating redispersible latex powder into putty formulations significantly enhances its properties, especially during the hardening process. The key benefits of RDP include improved workability, enhanced flexibility, increased strength and durability, reduced shrinkage, and better water resistance. These improvements make RDP-modified putties more suitable for both interior and exterior applications, providing greater longevity and performance under varying environmental conditions.

For construction professionals and manufacturers, the use of redispersible latex powder offers a simple yet effective way to upgrade the properties of traditional putty powders, resulting in a product that is easier to apply, more durable, and less prone to cracking or shrinkage over time. By optimizing the formulation with RDP, putty powders become more versatile, with enhanced overall performance in terms of adhesion, hardness, and resistance to the elements.

Post time: Mar-20-2025