Hydroxypropyl methylcellulose (HPMC) is a commonly used water-soluble polymer, widely used in pharmaceuticals, cosmetics, food and industrial fields, especially in the preparation of gels. Its physical properties and dissolution behavior have a significant impact on the effectiveness in different applications. The gelation temperature of HPMC gel is one of its key physical properties, which directly affects its performance in various preparations, such as controlled release, film formation, stability, etc.

1. Structure and properties of HPMC

HPMC is a water-soluble polymer obtained by introducing two substituents, hydroxypropyl and methyl, into the cellulose molecular skeleton. Its molecular structure contains two types of substituents: hydroxypropyl (-CH2CHOHCH3) and methyl (-CH3). Factors such as different hydroxypropyl content, degree of methylation, and degree of polymerization will have an important impact on the solubility, gelling behavior, and mechanical properties of HPMC.

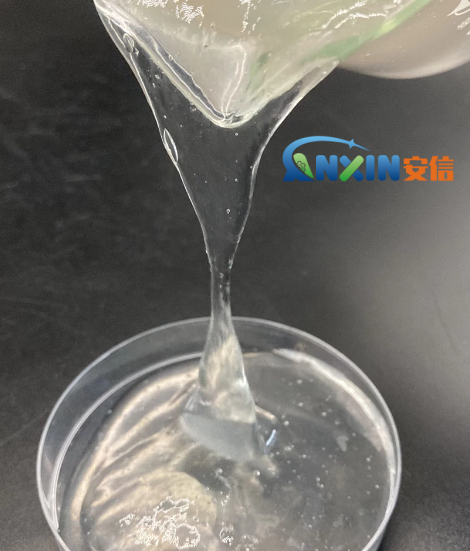

In aqueous solutions, AnxinCel®HPMC forms stable colloidal solutions by forming hydrogen bonds with water molecules and interacting with its cellulose-based skeleton. When the external environment (such as temperature, ionic strength, etc.) changes, the interaction between HPMC molecules will change, resulting in gelation.

2. Definition and influencing factors of gelation temperature

Gelation temperature (Gelation Temperature, T_gel) refers to the temperature at which the HPMC solution begins to transition from liquid to solid when the solution temperature rises to a certain level. At this temperature, the movement of HPMC molecular chains will be restricted, forming a three-dimensional network structure, resulting in a gel-like substance.

The gelation temperature of HPMC is affected by many factors, one of the most important factors is the hydroxypropyl content. In addition to hydroxypropyl content, other factors that affect gel temperature include molecular weight, solution concentration, pH value, solvent type, ionic strength, etc.

3. Effect of hydroxypropyl content on HPMC gel temperature

3.1 The increase in hydroxypropyl content leads to an increase in gel temperature

The gelation temperature of HPMC is closely related to the degree of hydroxypropyl substitution in its molecule. As the hydroxypropyl content increases, the number of hydrophilic substituents on the HPMC molecular chain increases, resulting in enhanced interaction between the molecule and water. This interaction causes the molecular chains to stretch further, thereby reducing the strength of the interaction between the molecular chains. Within a certain concentration range, increasing the hydroxypropyl content helps to enhance the degree of hydration and promotes the mutual arrangement of molecular chains, so that a network structure can be formed at a higher temperature. Therefore, the gelation temperature usually increases with the hydroxypropyl rises with increasing content.

HPMC with higher hydroxypropyl content (such as HPMC K15M) tends to exhibit a higher gelation temperature at the same concentration than AnxinCel®HPMC with lower hydroxypropyl content (such as HPMC K4M). This is because higher hydroxypropyl content makes it more difficult for molecules to interact and form networks at lower temperatures, requiring higher temperatures to overcome this hydration and promote intermolecular interactions to form a three-dimensional network structure. .

3.2 Relationship between hydroxypropyl content and solution concentration

Solution concentration is also an important factor affecting the gelation temperature of HPMC. In high-concentration HPMC solutions, the intermolecular interactions are stronger, so the gelation temperature may be higher even if the hydroxypropyl content is lower. At low concentrations, the interaction between HPMC molecules is weak, and the solution is more likely to gel at lower temperatures.

When the hydroxypropyl content increases, although the hydrophilicity increases, a higher temperature is still required to form a gel. Especially under low concentration conditions, the gelation temperature increases more significantly. This is because HPMC with high hydroxypropyl content is more difficult to induce interactions between molecular chains through temperature changes, and the gelation process requires additional thermal energy to overcome the hydration effect.

3.3 Effect of hydroxypropyl content on gelation process

Within a certain range of hydroxypropyl content, the gelation process is dominated by the interaction between hydration and molecular chains. When the hydroxypropyl content in the HPMC molecule is low, the hydration is weak, the interaction between molecules is strong, and a lower temperature can promote the formation of gel. When the hydroxypropyl content is higher, the hydration is significantly enhanced, the interaction between molecular chains becomes weaker, and the gelation temperature increases.

Higher hydroxypropyl content may also lead to an increase in the viscosity of the HPMC solution, a change that sometimes increases the onset temperature of gelation.

Hydroxypropyl content has a significant impact on the gelation temperature of HPMC. As the hydroxypropyl content increases, the hydrophilicity of HPMC increases and the interaction between molecular chains weakens, so its gelation temperature usually increases. This phenomenon can be explained by the interaction mechanism between hydration and molecular chains. By adjusting the hydroxypropyl content of HPMC, precise control of the gelation temperature can be achieved, thereby optimizing the performance of HPMC in pharmaceutical, food and other industrial applications.

Post time: Jan-04-2025