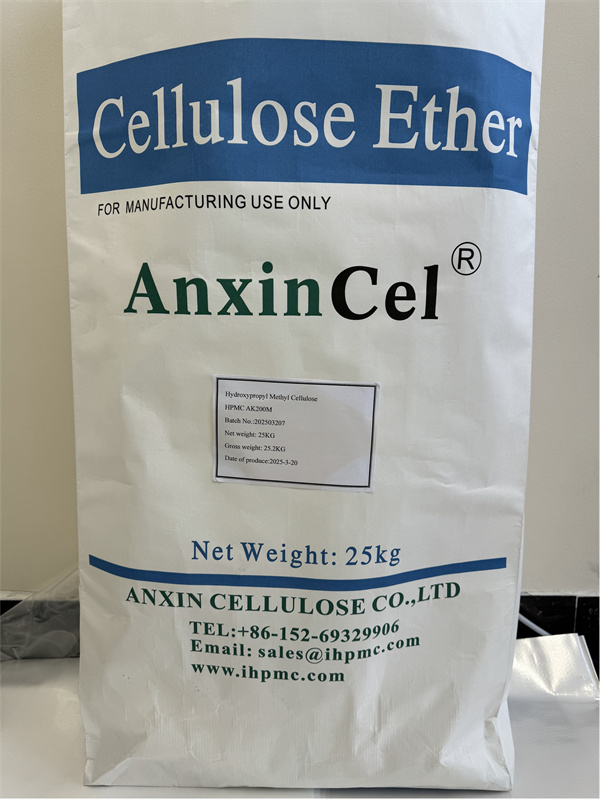

Hydroxypropyl Methylcellulose (HPMC) is a non-ionic cellulose ether widely used in building materials, especially in the field of tile laying. It is extracted from natural cellulose (such as cotton or wood pulp), and hydroxypropyl and methyl groups are introduced through chemical modification, thus giving it good water solubility, water retention, adhesion and construction adaptability.

1. The role of HPMC in tile laying

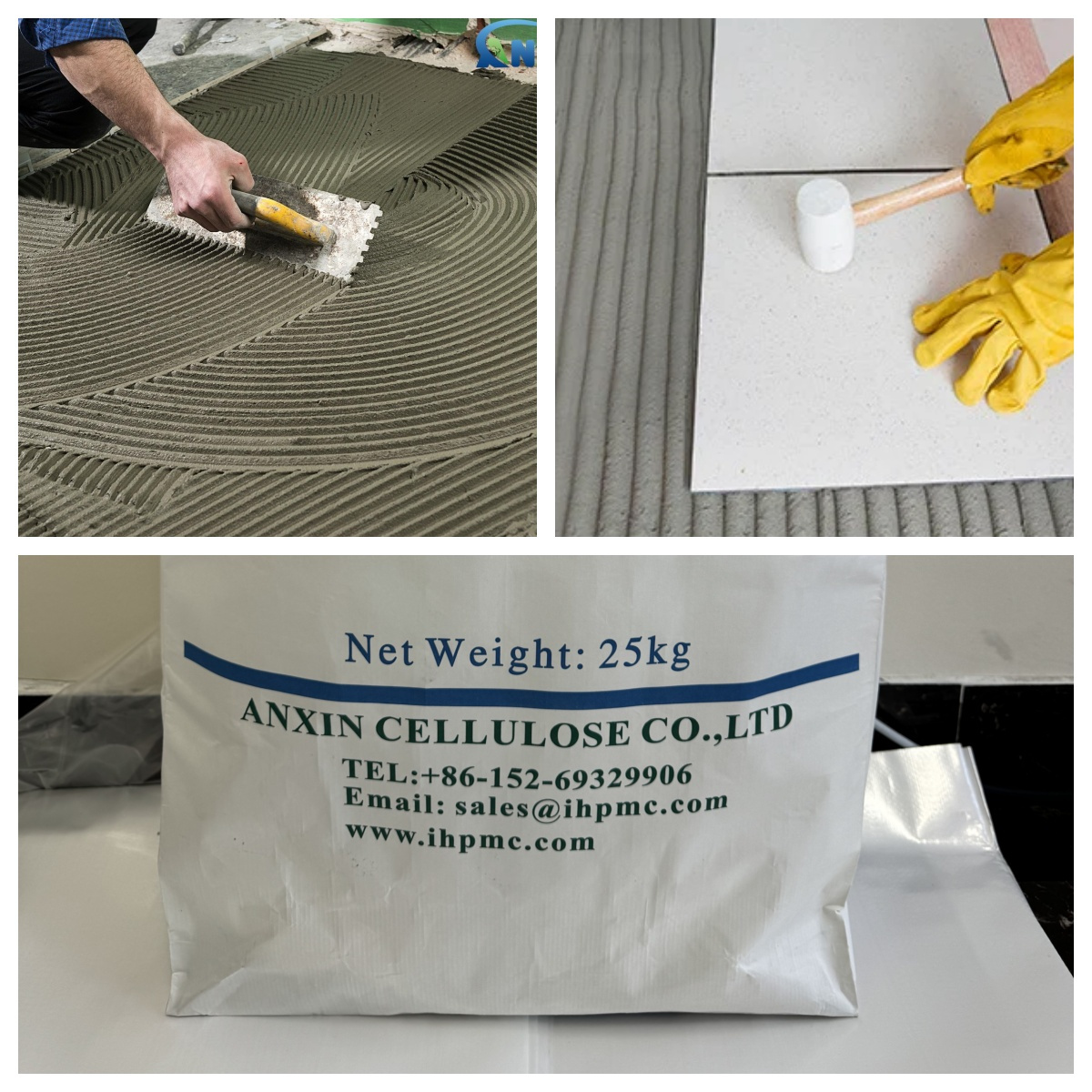

Improving construction performance

Adding HPMC to tile adhesive can significantly improve construction performance. It can adjust the consistency of tile adhesive, making it easier to spread evenly on the wall or floor, preventing sagging or sliding. It is particularly important for vertical tile laying conditions, which can improve construction efficiency and tile positioning accuracy.

Enhancing water retention

One of the most critical functions of HPMC is water retention. It can effectively lock in moisture and delay the rapid penetration of moisture into the substrate, thereby ensuring that inorganic cementitious materials such as cement have enough moisture for hydration reaction. This not only helps to improve the initial adhesion of tile adhesive, but also reduces the occurrence of hollowing and falling off.

Improve bond strength

HPMC forms a flexible film in cement mortar, which enhances the bonding performance between tile adhesive and tiles and the base layer. Its excellent film-forming property and flexibility make the dried tile adhesive layer both strong and crack-resistant, and can effectively adapt to the slight deformation of the wall or floor caused by temperature changes.

Extend open time and adjustment time

The so-called “open time” refers to the time that the tile adhesive can still maintain good bonding ability after being spread on the base surface. HPMC extends this time through good water retention, giving construction workers more room for operation, which is particularly important when constructing in high temperature or dry environment. At the same time, HPMC also extends the “adjustable time” of tiles, allowing construction workers to fine-tune the newly laid tiles to ensure the quality of paving.

Prevent cracking and powdering

After adding HPMC to tile adhesive or cement mortar, the overall flexibility of the material is enhanced, the shrinkage stress is relieved, and the risk of surface cracking caused by shrinkage, thermal expansion and contraction is reduced. At the same time, the film-forming ability of cellulose also makes the surface less likely to fall off, improving the apparent quality.

2. Features of HPMC

Strong solubility: HPMC can be quickly dispersed and dissolved in cold water to form a transparent solution without agglomeration.

Small dosage and significant effect: Its effective addition amount is usually 0.3%-1.0%, which can significantly improve the performance of tile adhesive, with high cost performance.

Good compatibility with other materials: HPMC can work well with various additives such as cement, quartz sand, latex powder, and redispersible polymers to improve the overall formulation performance.

Environmentally friendly and non-toxic: HPMC is a green and environmentally friendly material that is non-toxic, odorless, non-corrosive, and friendly to construction workers and the environment.

3. Application suggestions and precautions

Choose the right model

Different construction environments and tile types have different requirements for HPMC’s viscosity, degree of substitution, water solubility and other indicators. Generally, high-viscosity HPMC is suitable for vertical construction environments or large-sized tiles, which can better prevent slippage; while low-viscosity models are suitable for construction scenes with higher leveling requirements.

Storage conditions

HPMC should be stored in a cool, dry and ventilated environment, avoiding contact with moisture to prevent moisture and agglomeration.

Reasonable dosage control

Although the dosage of HPMC is not large, it has a significant impact on the performance. Excessive dosage may lead to long drying time or other side effects, so the dosage should be accurately controlled according to the specific formula.

As a key additive in tile laying materials HPMC plays an irreplaceable role in improving the water retention, construction performance, bonding strength and durability of tile adhesives. With the promotion of the concept of green building materials and the continuous advancement of modern construction technology, HPMC will continue to play an important role in tile laying and the entire construction materials industry. Choosing high-quality and adaptable HPMC products is an important guarantee for ensuring construction quality and durability.

Post time: Apr-18-2025