Hydroxypropyl methylcellulose (HPMC) is a water-soluble polymer widely used in industries such as construction, medicine, food and daily chemicals. In hot environments, HPMC has a series of significant advantages, which makes it show excellent stability and functionality in various applications.

1. Strong thermal stability and not easy to decompose

HPMC has high thermal stability and can still maintain the stability of its chemical structure at high temperatures. Its glass transition temperature (Tg) is high, generally around 200°C, so it will not decompose or fail due to temperature increases in hot environments. This enables HPMC to continue to perform thickening and water retention functions under high temperature conditions, and is suitable for industries such as building materials, coatings and pharmaceutical preparations.

2. Excellent water retention to prevent rapid evaporation of water

In high temperature environments, the evaporation rate of water is accelerated, which can easily cause the material to lose water and crack. However, HPMC has excellent water retention and can effectively reduce water loss. For example, in building mortar and gypsum-based materials, HPMC can maintain sufficient moisture at high temperatures, allowing cement or gypsum to fully react during the hydration process, thereby improving construction quality and preventing cracking and shrinkage.

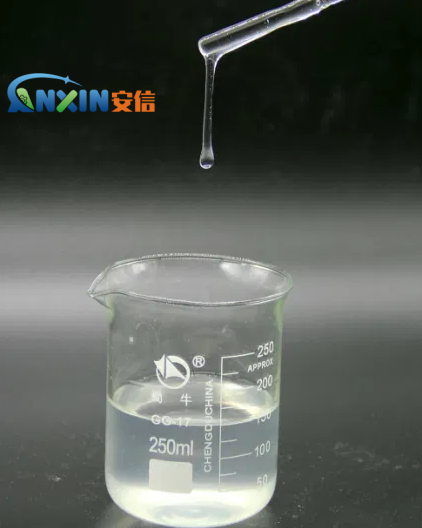

3. Stable thickening effect and maintenance of material rheological properties

HPMC is an effective thickener that can still maintain good viscosity and rheological properties in hot environments. Under high temperature conditions, some thickeners may fail or degrade due to increased temperature, while the viscosity of HPMC is relatively less affected by temperature, and can maintain suitable construction performance in high temperature environments and improve the operability of materials. For example, in the coatings industry, HPMC can prevent coatings from sagging at high temperatures and improve the uniformity and adhesion of coatings.

4. Good salt and alkali resistance, adaptability to complex environments

Under high temperature conditions, some chemicals may change and affect material properties. HPMC has good tolerance to electrolytes (such as salts and alkaline substances) and can maintain its functions in high temperature and high alkaline environments. This is particularly important in the building mortar, gypsum products and ceramic industries, because these materials often need to be applied at high temperatures and exposed to alkaline environments.

5. Thermal gelation properties, can be used for special high temperature applications

HPMC has a unique thermal gelation property, that is, its aqueous solution will gel within a certain temperature range. This property can be used in some high temperature applications. For example, in the food industry, HPMC can be used to produce instant noodles. As the temperature rises, it can form a stable gel, improving the taste and morphological stability of the food. In the pharmaceutical industry, the thermal gelation property of HPMC can also be used in the preparation of controlled-release drugs to ensure the stability of the drug release rate under different temperature conditions.

6. Eco-friendly, non-toxic and harmless

HPMC is a safe and non-toxic polymer material that will not release harmful substances or produce odors under high temperature conditions. Compared with some thickeners or additives that may release volatile organic compounds (VOCs) at high temperatures, HPMC is more environmentally friendly and meets the requirements of modern sustainable development. Therefore, HPMC is an ideal choice in fields such as high temperature construction or food processing.

7. Applicable to a variety of high temperature environment applications

These advantages of HPMC make it widely applicable to various high temperature environments. For example:

Construction industry: used in cement mortar, tile adhesive, and gypsum products to improve water retention and construction performance and prevent excessive evaporation of water caused by high temperature.

Coating industry: used in water-based coatings and latex paints to maintain rheological stability and prevent sagging in high temperature environments.

Food industry: used in baked goods and fast food products to improve the stability of food during high temperature processing.

Pharmaceutical industry: used in sustained-release tablets and gel preparations to ensure the stability and bioavailability of drugs under high temperature conditions.

HPMC has excellent thermal stability, water retention, thickening, alkali resistance and environmental protection properties in hot environments, and can be widely used in many fields such as construction, coatings, food and medicine. Its stable performance under high temperature conditions enables related products to maintain excellent functions in extreme environments, thereby improving the quality of production and construction, reducing material loss, and ensuring the reliability of the final product.

Post time: Apr-07-2025