Hydroxypropyl Methylcellulose (HPMC) is a chemically modified form of cellulose that is widely used in a variety of industries such as pharmaceuticals, food production, and construction. It is a versatile compound, often used as a thickener, binder, film-forming agent, and stabilizer. However, it does not have a specific “serial number” in the traditional sense, like a product or part number you might find in other manufacturing contexts. Instead, HPMC is identified by its chemical structure and a number of characteristics, such as the degree of substitution and viscosity.

General Information About Hydroxypropyl Methylcellulose (HPMC)

Chemical Structure: HPMC is made by chemically modifying cellulose through the substitution of hydroxyl (-OH) groups with hydroxypropyl and methyl groups. The substitution alters the properties of cellulose, making it more soluble in water and giving it its unique properties like improved film-forming ability, binding capability, and ability to retain moisture.

Common Identifiers and Naming

The identification of Hydroxypropyl Methylcellulose typically relies on a variety of naming conventions that describe its chemical structure and properties:

CAS Number:

The Chemical Abstracts Service (CAS) assigns a unique identifier to every chemical substance. The CAS number for Hydroxypropyl Methylcellulose is 9004-65-3. This is a standardized number used by chemists, suppliers, and regulatory bodies to refer to the substance.

InChI and SMILES Codes:

InChI (International Chemical Identifier) is another way to represent the chemical structure of a substance. HPMC would have a long InChI string that represents its molecular structure in a standardized format.

SMILES (Simplified Molecular Input Line Entry System) is another system used to represent molecules in a text form. HPMC also has a corresponding SMILES code, though it would be highly complex due to the large and variable nature of its structure.

Product Specifications:

In the commercial market, HPMC is often identified by product numbers, which can vary by manufacturer. For example, a supplier might have a grade like HPMC K4M or HPMC E15. These identifiers often refer to the viscosity of the polymer in solution, which is determined by the degree of methylation and hydroxypropylation as well as the molecular weight.

Typical Grades of Hydroxypropyl Methylcellulose (HPMC)

The characteristics of Hydroxypropyl Methylcellulose vary based on the degree of substitution of the methyl and hydroxypropyl groups, as well as the molecular weight. These variations determine the HPMC’s viscosity and solubility in water, which in turn affects its applications in different industries.

Below is a table that outlines the different grades of Hydroxypropyl Methylcellulose:

|

Grade |

Viscosity (cP in 2% solution) |

Applications |

Description |

| HPMC K4M | 4000 – 6000 cP | Pharmaceutical tablet binder, food industry, construction (adhesives) | Medium viscosity grade, commonly used in oral tablet formulations. |

| HPMC K100M | 100,000 – 150,000 cP | Controlled-release formulations in pharmaceuticals, construction, and paint coatings | High viscosity, excellent for controlled release of drugs. |

| HPMC E4M | 3000 – 4500 cP | Cosmetics, toiletries, food processing, adhesives, and coatings | Soluble in cold water, used in personal care products and food items. |

| HPMC E15 | 15,000 cP | Thickening agent in paints, coatings, food, and pharmaceuticals | High viscosity, soluble in cold water, used in industrial and pharmaceutical products. |

| HPMC M4C | 4000 – 6000 cP | Food and beverage industry as a stabilizer, pharmaceutical as a binder | Moderate viscosity, often used as a thickener in processed food. |

| HPMC 2910 | 3000 – 6000 cP | Cosmetics (creams, lotions), food (confectionery), pharmaceutical (capsules, coatings) | One of the most common grades, used as a stabilizing and thickening agent. |

| HPMC 2208 | 5000 – 15000 cP | Used in cement and plaster formulations, textiles, paper coatings | Good for applications requiring excellent film-forming properties. |

Detailed Composition and Properties of HPMC

The physical properties of Hydroxypropyl Methylcellulose depend largely on the extent of substitution of the hydroxyl groups in the cellulose molecule. Here are the major properties:

Degree of Substitution (DS):

This refers to how many of the hydroxyl groups in cellulose have been substituted by methyl or hydroxypropyl groups. The degree of substitution impacts the solubility of HPMC in water, its viscosity, and its ability to form films. The typical DS for HPMC ranges from 1.4 to 2.2, depending on the grade.

Viscosity:

HPMC grades are categorized based on their viscosity when dissolved in water. The higher the molecular weight and the degree of substitution, the higher the viscosity. For example, HPMC K100M (with a higher viscosity range) is often used in controlled-release drug formulations, whereas lower viscosity grades like HPMC K4M are commonly used for tablet binders and food applications.

Water Solubility:

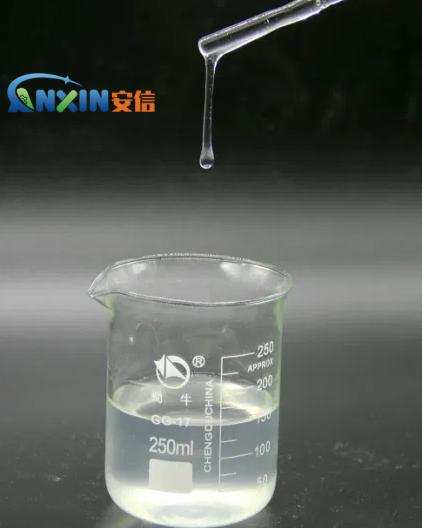

HPMC is soluble in water and forms a gel-like substance when dissolved, but the temperature and pH can influence its solubility. For instance, in cold water, it dissolves quickly, but its solubility may be reduced in hot water, especially at higher concentrations.

Film-Forming Ability:

One of the key features of Hydroxypropyl Methylcellulose is its ability to form a flexible film. This property makes it suitable for use in tablet coatings, where it provides a smooth, controlled-release surface. It is also useful in the food industry to improve texture and shelf life.

Gelation:

At certain concentrations and temperatures, HPMC can form gels. This property is beneficial in pharmaceutical formulations, where it is used to create controlled-release systems.

Applications of Hydroxypropyl Methylcellulose

Pharmaceutical Industry:

HPMC is used as a binder in tablet formulations, particularly in extended-release and controlled-release systems. It also serves as a coating agent for tablets and capsules to control the release of the active ingredient. Its ability to form stable films and gels is ideal for drug delivery systems.

Food Industry

In the food industry, HPMC is used as a thickening agent, emulsifier, and stabilizer in a variety of products, including sauces, dressings, and baked goods. It helps improve texture and extend shelf life by reducing moisture loss.

Cosmetics and Personal Care:

HPMC is widely used in cosmetics, where it acts as a thickener and stabilizer in creams, lotions, shampoos, and other personal care products. Its ability to form a gel structure is particularly useful in these applications.

Construction Industry:

In the construction industry, particularly in cement and plaster formulations, HPMC is used as a water-retaining agent. It helps improve workability and enhances the bonding properties of materials.

Other Applications:

HPMC is also employed in the textile industry, paper coatings, and even in the production of biodegradable films.

Hydroxypropyl Methylcellulose (HPMC) is a highly versatile compound used across multiple industries due to its unique properties such as film-forming ability, thickening capability, and water retention. While it doesn’t have a “serial number” in the conventional sense, it is identified by chemical identifiers like its CAS number (9004-65-3) and product-specific grades (e.g., HPMC K100M, HPMC E4M). The diverse range of HPMC grades available ensures its applicability in different fields, from pharmaceuticals to food, cosmetics, and construction.

Post time: Mar-21-2025